Science

PhysicsX Secures Up to $100 Million from Nvidia to Innovate Manufacturing

PhysicsX, a pioneering startup focused on revolutionizing part design for the defence and aerospace sectors, aims to raise up to $100 million from Nvidia, a leading global chip manufacturer. The company’s advanced platform facilitates the rapid development of manufacturing components by simulating material behaviours and engineering designs under various conditions. This innovation is set to significantly transform the pace and cost structure of manufacturing in complex industries.

Nvidia’s financial commitment follows PhysicsX’s $20 million funding round in June and a successful $135 million Series B round concluded earlier this year. Nvidia’s involvement underscores its growing interest in European startups that align with its hardware and software ecosystems. As part of this investment, Nvidia retains the option to inject another $80 million into PhysicsX during its next capital raise, indicating a long-term partnership.

Nvidia’s Chief Executive Officer, Jensen Huang, has publicly stated his dedication to investing billions in UK-based startups, with PhysicsX emerging as one of the most promising beneficiaries of this strategy. This collaboration highlights Nvidia’s broader initiative to expand into diverse technology sectors across Europe, including workflow automation, molecule discovery, and generative platforms.

Revolutionizing Manufacturing Processes

PhysicsX, founded in 2019 by former Formula 1 engineers Jacomo Corbo and Robin Tuluie, has gained notable attention for its software’s capacity to reduce the need for physical prototypes. The platform’s simulation engines empower manufacturers to iterate product designs quickly, thereby significantly reducing development timelines and associated costs. This capability is particularly valuable in defence and aerospace, where precision and reliability are paramount, and the costs of trial and error are substantial.

The technology developed by PhysicsX is not confined to its core sectors; it also serves industries such as semiconductor fabrication, automotive, energy, and materials science. Major clients, including Rio Tinto, Siemens, and Applied Materials, rely on PhysicsX’s tools to enhance their innovation processes and improve product durability.

Transforming Design Cycles with Advanced Simulation

PhysicsX’s platform addresses one of the most challenging aspects of manufacturing: predicting how parts will perform under real-world stresses without incurring the costs associated with physical testing. By leveraging sophisticated computational models, the company equips engineers with vital insights that significantly reduce the trial-and-error phase of product development. This approach is especially critical in sectors where product failures can have serious implications, such as in defence and aerospace.

In addition to accelerating product design cycles, PhysicsX’s software enhances confidence in the reliability of components. With its cutting-edge technology and substantial financial backing, PhysicsX is well-positioned to redefine manufacturing innovation on a global scale. Combining advanced simulation techniques with real-world engineering expertise derived from high-performance racing, the company is set to make a lasting impact across multiple industries.

-

Entertainment3 months ago

Entertainment3 months agoAnn Ming Reflects on ITV’s ‘I Fought the Law’ Drama

-

Entertainment4 months ago

Entertainment4 months agoKate Garraway Sells £2 Million Home Amid Financial Struggles

-

Health3 months ago

Health3 months agoKatie Price Faces New Health Concerns After Cancer Symptoms Resurface

-

Entertainment3 months ago

Entertainment3 months agoCoronation Street’s Carl Webster Faces Trouble with New Affairs

-

Entertainment3 months ago

Entertainment3 months agoWhere is Tinder Swindler Simon Leviev? Latest Updates Revealed

-

Entertainment4 months ago

Entertainment4 months agoMarkiplier Addresses AI Controversy During Livestream Response

-

Science1 month ago

Science1 month agoBrian Cox Addresses Claims of Alien Probe in 3I/ATLAS Discovery

-

Health4 months ago

Health4 months agoCarol Vorderman Reflects on Health Scare and Family Support

-

Entertainment4 months ago

Entertainment4 months agoKim Cattrall Posts Cryptic Message After HBO’s Sequel Cancellation

-

World2 weeks ago

World2 weeks agoBailey Announces Heartbreaking Split from Rebecca After Reunion

-

Entertainment3 months ago

Entertainment3 months agoOlivia Attwood Opens Up About Fallout with Former Best Friend

-

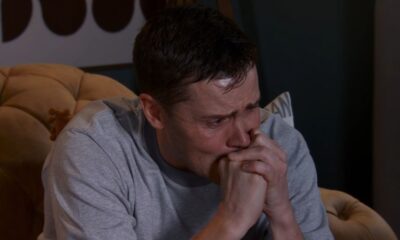

Entertainment2 weeks ago

Entertainment2 weeks agoCoronation Street Fans React as Todd Faces Heartbreaking Choice