Business

Jamieson’s Spinning Invests in Advanced Technology for Growth

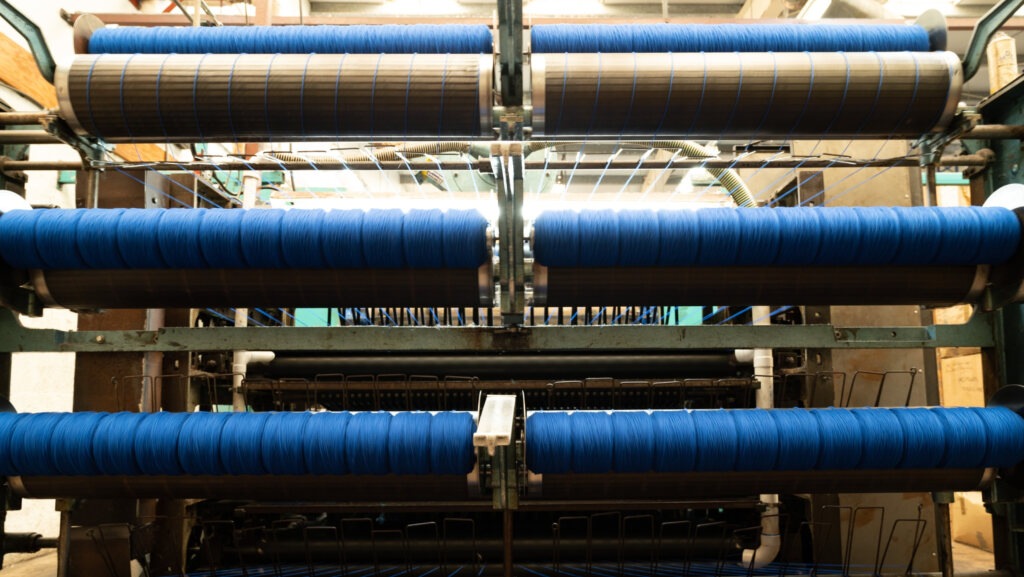

The operators of Shetland’s only commercial woollen mill, Jamieson’s Spinning (Shetland) Ltd, have announced a significant investment aimed at enhancing their production capabilities. The company has installed a state-of-the-art vacuum fettling system on its carding machines, which is expected to streamline operations by reducing manual cleaning time by 75 percent. This improvement follows a financial boost of over £32,000 from Highlands and Islands Enterprise (HIE).

Enhancing Efficiency and Quality

This investment is poised to greatly increase production efficiency and yarn quality while also improving the working environment for employees. Additionally, it is projected to create 1.5 new jobs, contributing to the local economy. HIE’s area manager, Katrina Wiseman, highlighted the initiative’s broader impact, stating, “This is a great example of how innovation can support rural business growth.” She added that the project not only enhances productivity but also strengthens the international competitiveness of Shetland’s textile industry, supporting jobs and communities in the region.

Established in 1981, the mill processes Shetland wool from fleece to finished yarn, offering a diverse range of over 400 colours in five different weights. With this latest technological advancement, Jamieson’s is positioned to further bolster Shetland’s rich textile heritage.

Positive Impacts on Workforce and Production

Garry Jamieson, a representative from Jamieson’s Spinning, expressed enthusiasm about the new vacuum system, describing it as an “amazing addition” to their carding machines. He noted that upgrades like this can extend the lifespan of existing machinery, emphasizing the physical demands of manual fettling, which can be strenuous for staff. “This should make a big difference to our great staff,” he said.

In addition to the new vacuum system, Jamieson mentioned that the mill is also replacing card cloth to further improve yarn quality. The new fettling system is designed to clean without damaging the cloth, which is an added advantage. He reflected on the mill’s ongoing commitment to improvement, stating, “Over the last 10-15 years, we have been constantly looking for ways we can improve productivity here in the mill. We have done a number of projects, but this is by far the biggest investment to date.”

HIE has encouraged other businesses in Shetland with innovative ideas to reach out and explore potential support for their growth ambitions. The investment in Jamieson’s Spinning reflects a broader trend of leveraging technology to enhance traditional industries, ensuring their sustainability and relevance in a competitive market.

-

Entertainment3 months ago

Entertainment3 months agoAnn Ming Reflects on ITV’s ‘I Fought the Law’ Drama

-

Entertainment4 months ago

Entertainment4 months agoKate Garraway Sells £2 Million Home Amid Financial Struggles

-

Health3 months ago

Health3 months agoKatie Price Faces New Health Concerns After Cancer Symptoms Resurface

-

Entertainment3 months ago

Entertainment3 months agoCoronation Street’s Carl Webster Faces Trouble with New Affairs

-

Entertainment3 months ago

Entertainment3 months agoWhere is Tinder Swindler Simon Leviev? Latest Updates Revealed

-

Entertainment4 months ago

Entertainment4 months agoMarkiplier Addresses AI Controversy During Livestream Response

-

Science1 month ago

Science1 month agoBrian Cox Addresses Claims of Alien Probe in 3I/ATLAS Discovery

-

World2 weeks ago

World2 weeks agoBailey Announces Heartbreaking Split from Rebecca After Reunion

-

Health4 months ago

Health4 months agoCarol Vorderman Reflects on Health Scare and Family Support

-

Entertainment4 months ago

Entertainment4 months agoKim Cattrall Posts Cryptic Message After HBO’s Sequel Cancellation

-

Entertainment3 months ago

Entertainment3 months agoOlivia Attwood Opens Up About Fallout with Former Best Friend

-

Entertainment2 weeks ago

Entertainment2 weeks agoCoronation Street Fans React as Todd Faces Heartbreaking Choice