Business

How Precision Power Supplies Drive Innovation in Electronics

The global market for programmable power solutions has reached an impressive $4.2 billion in 2024, with a projected growth rate of nearly 6% annually. This expansion is primarily driven by increasing applications in sectors such as renewable energy, electric vehicles, and consumer electronics. Despite their critical role in innovation, precision power supplies often remain underappreciated by those outside engineering fields.

Understanding the Importance of Precision Power

Before any electronic product hits the market, it undergoes extensive testing and validation processes. Engineers rely on precision power sources to simulate various power conditions, ensuring devices perform reliably under different scenarios. Unlike alternating current (AC), which flows in both directions, direct current (DC) maintains a steady direction and is the primary power source for most electronic devices, including laptops and industrial controllers.

During product development, engineers must exert precise control over voltage and current levels. Modern electronic components operate within tight tolerances, where even a minor voltage fluctuation can lead to catastrophic failures. Quality test instruments ensure voltage regulation accuracy within 0.01% or better, allowing engineers to identify potential issues before products enter mass production. This proactive approach can save companies millions of dollars in recalls or redesigns.

Engineers also simulate worst-case scenarios, such as voltage surges or sags. Programmable power units can replicate these conditions accurately, facilitating more comprehensive validation testing than traditional power sources. The automation of these tests through computer control enhances the quality assurance processes across various industries.

Applications Across Industries

The versatility of modern test equipment extends far beyond traditional electronics manufacturing. In the automotive sector, engineers developing electric vehicle battery management systems depend on power sources that can deliver hundreds of amps while maintaining precise voltage control. These tools are equally essential for testing charging infrastructure and validating power electronics that manage electricity within vehicles.

Renewable energy researchers utilize sophisticated instruments to test solar inverters, wind turbine controllers, and energy storage systems. As the global community transitions toward sustainable energy, the ability to simulate diverse generation and load conditions becomes crucial for optimizing system efficiency and reliability. Telecommunications companies also rely on precision power sources to validate equipment designed to operate continuously for years, often in remote areas where service disruptions are costly.

The evolution of power conversion technology has paralleled advancements in semiconductor devices and digital control systems. Early linear designs were inefficient, often converting excess energy into heat. In contrast, modern switching designs achieve efficiency levels exceeding 90%, enhancing performance characteristics while providing programmability for sophisticated testing protocols.

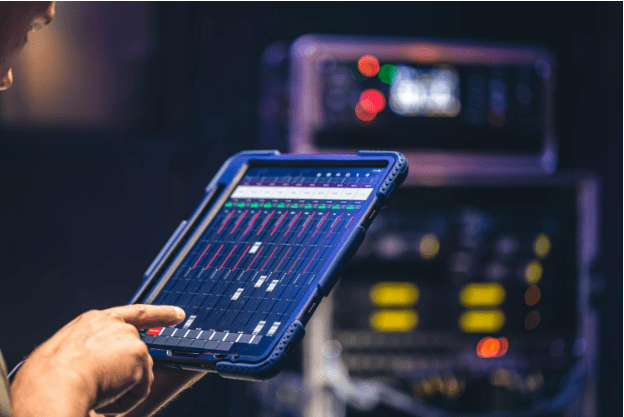

Today’s high-performance units incorporate microprocessor control, enabling engineers to program complex voltage and current sequences, set precise timing parameters, and capture detailed measurement data. Features such as overvoltage protection and current limiting ensure operator safety and measurement accuracy.

When selecting power test equipment, engineers must consider several critical specifications to ensure suitability and performance. Voltage and current ranges must align with the requirements of the devices under test, and regulation specifications indicate how well the unit maintains set values under varying load conditions. Ripple and noise measurements reveal the quality of the DC output, while response time becomes vital when testing devices that require swift changes in current.

Emerging trends in the precision power industry are responding to new challenges presented by advancing technology. The introduction of wide bandgap semiconductors, such as silicon carbide and gallium nitride, enables faster switching speeds and higher efficiency, which in turn requires more sophisticated test equipment. Modern instruments must deliver cleaner outputs with lower noise levels while responding to load transients in microseconds.

The rise of electric vehicles and renewable energy systems has created a demand for high-power units capable of testing components that manage kilowatts or even megawatts. Battery testing applications now require bidirectional capabilities, where the unit can both source and sink power, simulating charging and discharging cycles. Such regenerative designs can return energy to the grid, significantly reducing operational costs in high-power testing facilities.

Increasingly, automated test systems are becoming standard in manufacturing and R&D environments, capable of running 24/7 with minimal human intervention. Programmable power sources with comprehensive interfaces and built-in measurement capabilities integrate seamlessly into these systems, allowing engineers to create sophisticated test sequences that adjust power conditions automatically.

Cloud connectivity and Internet of Things (IoT) integration represent the next frontier for precision power. These advancements enable remote monitoring and control of test equipment, allowing engineers to access instrument settings and measurement data from virtually anywhere. Machine learning algorithms can analyze patterns to predict maintenance needs or optimize testing procedures, transforming individual instruments into integral nodes within a comprehensive test ecosystem.

In conclusion, selecting the appropriate test equipment requires careful consideration of both current and anticipated future needs. Engineers should begin with a clear understanding of voltage and current requirements and take into account how applications might evolve. While a unit with programmability and automation features may entail a higher initial investment, the long-term value is evident as test requirements change and grow.

Quality and reliability are paramount in professional applications, where downtime directly equates to lost productivity. Established manufacturers with strong technical support can provide essential guidance on optimal configurations and address any issues that arise swiftly. The total cost of ownership encompasses more than just the purchase price; it also includes efficiency, maintenance requirements, and adaptability to changing needs.

For organizations committed to innovation and quality, investing in the right test equipment yields significant dividends. Precision power instruments may not be glamorous, but they are indispensable tools that underpin advancements in electronics and drive the industry forward.

-

World3 days ago

World3 days agoCoronation Street’s Shocking Murder Twist Reveals Family Secrets

-

Entertainment4 months ago

Entertainment4 months agoKate Garraway Sells £2 Million Home Amid Financial Struggles

-

Entertainment3 months ago

Entertainment3 months agoAnn Ming Reflects on ITV’s ‘I Fought the Law’ Drama

-

Health3 months ago

Health3 months agoKatie Price Faces New Health Concerns After Cancer Symptoms Resurface

-

Entertainment3 weeks ago

Entertainment3 weeks agoCoronation Street Fans React as Todd Faces Heartbreaking Choice

-

World4 weeks ago

World4 weeks agoBailey Announces Heartbreaking Split from Rebecca After Reunion

-

Entertainment6 days ago

Entertainment6 days agoTwo Stars Evicted from I’m A Celebrity Just Days Before Finale

-

World6 days ago

World6 days agoKevin Sinfield Exceeds Fundraising Goal Ahead of Final Marathons

-

Entertainment3 months ago

Entertainment3 months agoCoronation Street’s Carl Webster Faces Trouble with New Affairs

-

Entertainment3 months ago

Entertainment3 months agoWhere is Tinder Swindler Simon Leviev? Latest Updates Revealed

-

Entertainment4 months ago

Entertainment4 months agoMarkiplier Addresses AI Controversy During Livestream Response

-

Science2 months ago

Science2 months agoBrian Cox Addresses Claims of Alien Probe in 3I/ATLAS Discovery